I understand some of what you are describing…

act up is just slang or lazy for RPM.

I was unaware of the frequency of an average DC control. So, does it seem normal to handle chips in a way that is leaning towards PWM over GPIO?

I will look over the PWMClass_BBB repo. but I think I am misguiding you on what I actually am trying to get across.

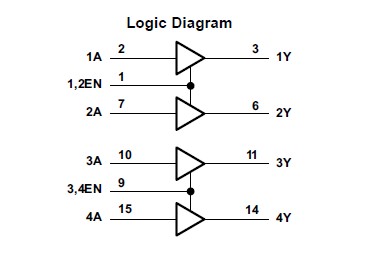

What set of transistor logic would I need to understand to handle an off-board chip selection of PWM over GPIO?

For instance, there is a missing link. I can perform and do things in the beagleboard.org world but not completely with Buildroot and/or a fresh install of Linux.

It is like all the books I read were geared towards children and learning curves. So, I got fed up, bored, and pretended I was smart. I am not so smart (I think).

So anyway, is there some type of transistor logic in the, say L293D, that attempts to allow for PWM usage over GPIO? And this could be a vice versa scenario. It is PWM over GPIO? Or, it is GPIO over PWM?

I know they both can be incorporated in specific hardware but what is this hardware? Let me start with the L293D. It can be controlled via GPIO for a bipolar motor.

Anyway, I hope this makes more sense now. I am performing catch up work and trying to tie pieces together where I am not fully educated in the subject matter.

I have seen source code, the docs.beagleboard.org pages, and there is even a nice portion dedicated to Motors in the docs pages (my favorite subject that gives me the most strain).

Anyway, if you have more time to boast about your understandings, please direct them at me while I am putting pieces together slowly.

I did type up a very long versioning of this “letter” to the editor(s) but I have discarded it and left it with this one instead.

I read about adder logic in gates and other technologies but there is a good portion that I missed that I have not quite placed.

- https://www.allaboutcircuits.com/textbook/digital/chpt-3/cmos-gate-circuitry/

- Binary Adder with Logic Gates - GeeksforGeeks

So, because I have no real hardware, assuming since I really do not know now, to test. For now for basic logic without getting down to bare technology, I am relying on chips to handle this building of hardware and their internal components are not always a given.

Example One: I read datasheets. I get data from the mfg. TRM and/or datasheets.

Example Two: Within the circuit, so-said selected chip, are some characteristics of what, where, and how but why is not always available. And who has no value since it is actual hardware being discussed (not human).

What: What are my values? L293D datasheets state …

Update

Scratch what I am saying. I need to put the pieces together. It seems that, like with the L293D from ti, I am oblivious to the logic within the chip and it is a given. I just understood something from typing a ton of garbage that people may or may not read.

The logic is not for action. The logic is so one can understand what is transpiring within the chip that is being used.

I am eating my own words as I type. Yay.

For instance:

I am silly to use random drivers with no data. If something happens and I do not know why it happened, I really do not learn in this aspect to my conclusive journey. Again, sorry for my antics. I was using hidden data willingly and not liking it. Unlike the L293D, obviously, from ti, not all companies are pushing the agenda of Open Source hardware rightfully.

This is something I am slowly piecing together now.