Hello There,

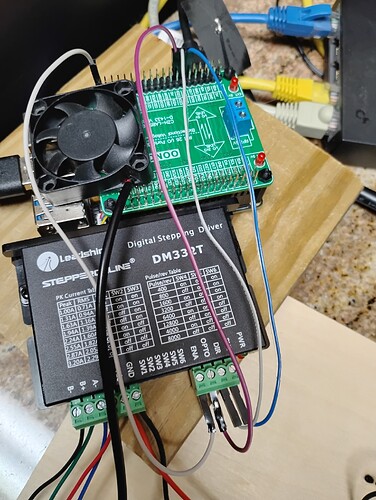

I am using a logic level shifter and some Python3 source to test the BeagleY-AI. My stepper motor driver is a DM332T.

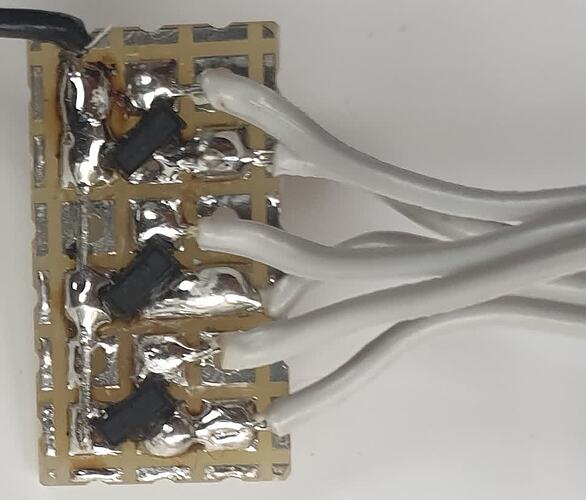

This is the item for level shifting:

Has anyone used this level shifter successfully with the BeagleY-AI? If yes and if you have used it successfully, please reply with some type of data that I can use.

Seth

P.S. With the DM332T, my PSU/Bench Supply shuts down when I run the Python3 source which is found below:

#!/usr/bin/python3

import gpiod

import time

gpio12 = gpiod.find_line('GPIO12')

gpio12.request(consumer='beagle', type=gpiod.LINE_REQ_DIR_OUT, default_val=0)

gpio6 = gpiod.find_line('GPIO6')

gpio6.request(consumer='beagle', type=gpiod.LINE_REQ_DIR_OUT, default_val=0)

gpio13 = gpiod.find_line('GPIO13')

gpio13.request(consumer='beagle', type=gpiod.LINE_REQ_DIR_OUT, default_val=0)

try:

gpio13.set_value(1)

time.sleep(0.5)

while True:

gpio6.set_value(1)

gpio12.set_value(1)

time.sleep(4)

gpio6.set_value(0)

gpio12.set_value(1)

time.sleep(4)

except KeyboardInterrupt:

gpio13.set_value(0)

pass

print("Hey!")

I got most of the source from the docs.beagleboard.org page under the header BeagleY-AI.