In looking for a female header receptacle to fit on the top of the board, to accept the Click ETH-WIZ Ethernet daughter card, so far, I have only found one brand of receptacle that I can make fit.

I would normally expect connectors for the 0.1 inch grid system to be 0.100 inches wide for single row, and 0.200 inches wide for the dual row.

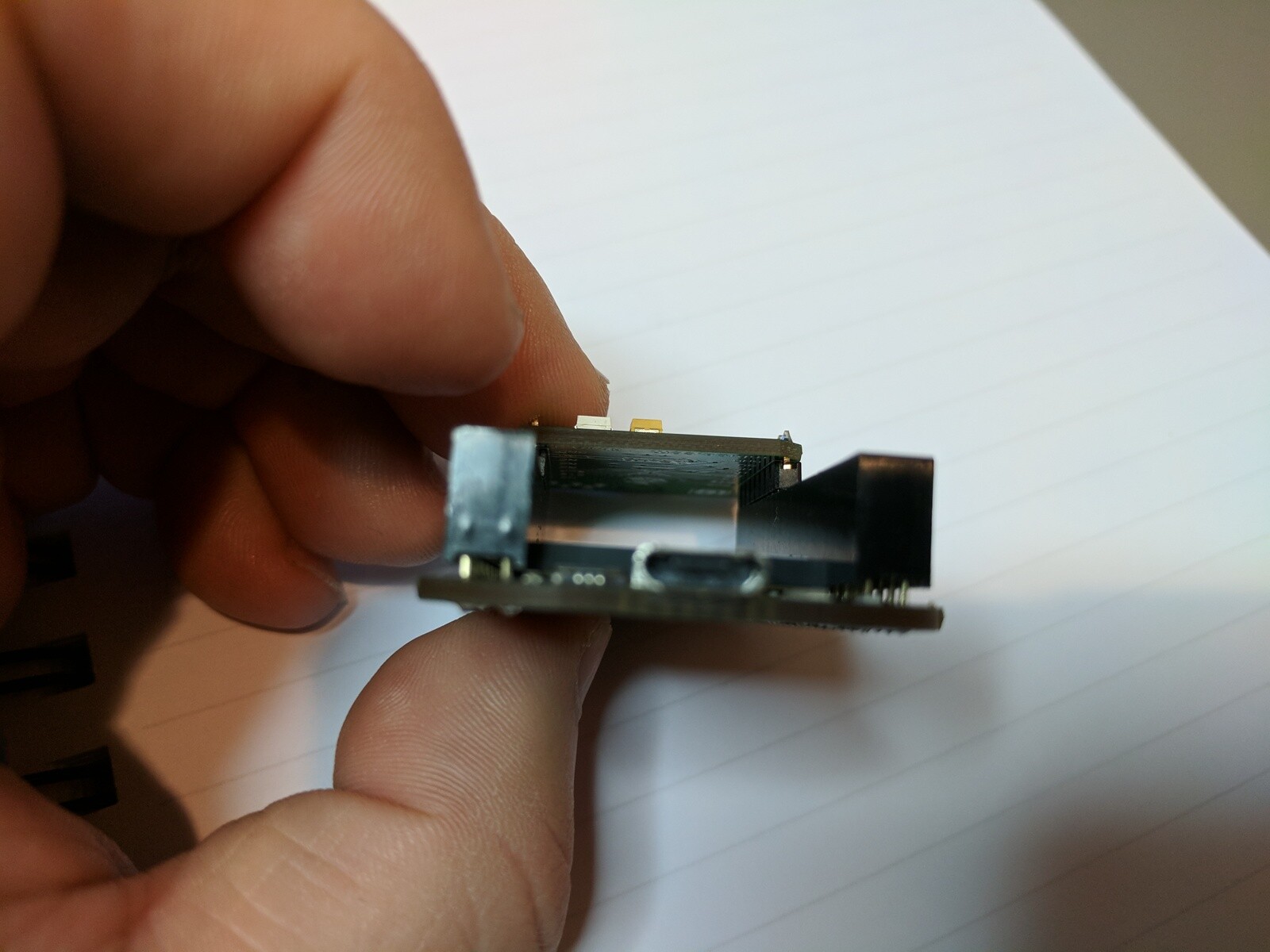

The Molex CGrid-III series, dual row female, is only 0.195 inches wide at the base and will fit on either side of the Octavo chip, and also fit flat against the PC board, without forcing, so the connector is vertical.

Line-to-line fit without clearance, but it does fit.

The 3M series is 0.201 inches wide at the base, and there is no way to use that connector on the PocketBeagle.

I have some Amphenol-FCI connectors on order, but they were delayed in shipping, so no results yet.

The Molex cost more, and are only stocked in distribution with tin mating surface (gold flash exists, but no stock found in distribution.)

The Molex is not available in a 36 pin version (18x2), but you can do something like a 20 and a 16 to populate all positions. (an 18 pin exists, but no stock found in distribution.)

Molex C-Grid-III series, dual row female, tin contacts

Following stocked at both Mouser and Digikey

90151-2116 16 position (8x2)

90151-2120 20 position (10x2)

If someone has another vendor and part number that will fit, I would like to hear about it.

— Graham